Microstructure and property optimisation in hot rolling processes

Hot rolled metal is a key material in the metalworking industry that is produced through the process of hot rolling. This process takes place at temperatures well above the recrystallisation temperature of the metal being processed, typically between 1000 °F (538 °C) and 1300 °F (704 °C) for steel. Heating above this critical temperature makes the metal more pliable and allows the material to be effectively moulded and stretched without breaking.

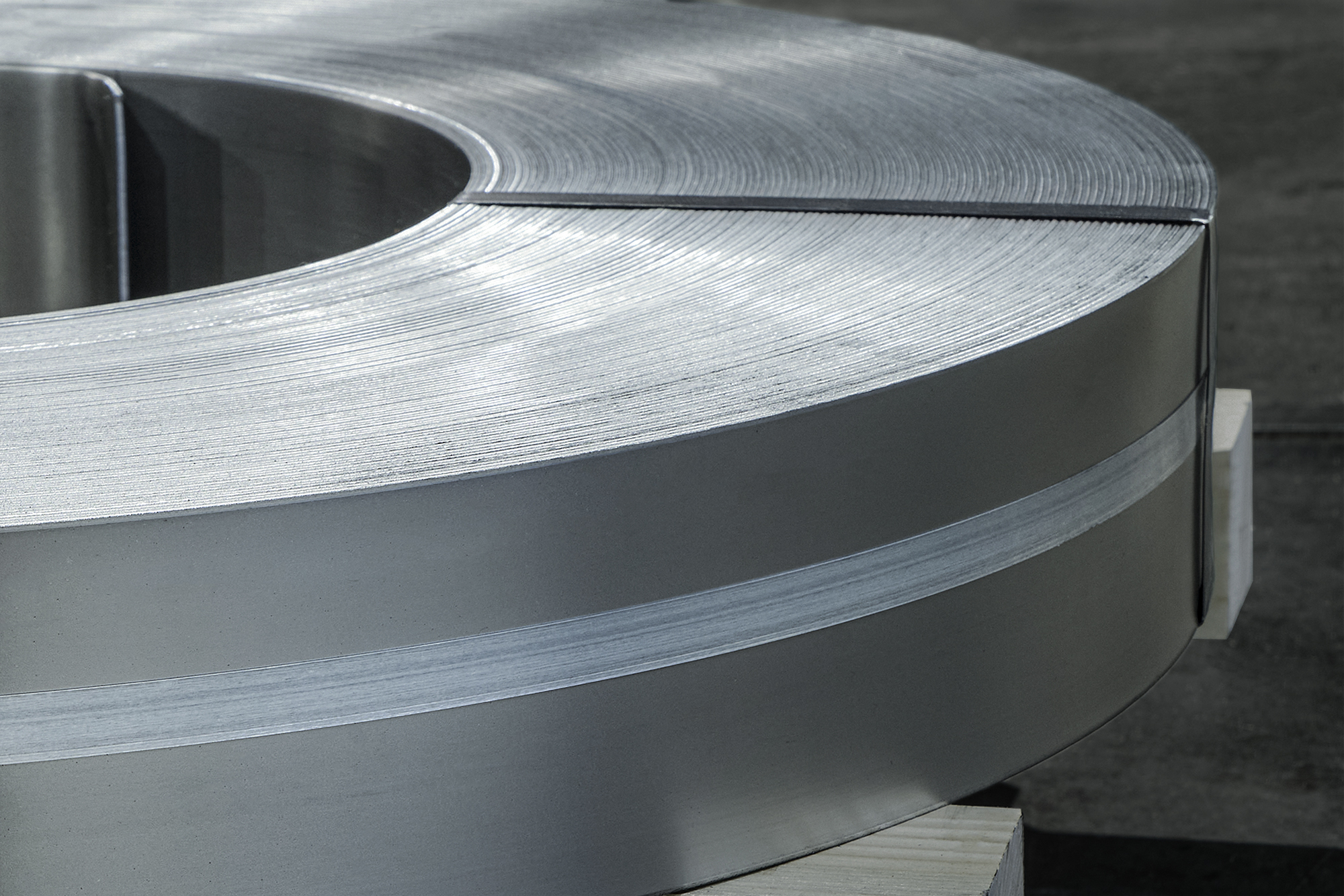

Optimisation of steel properties through cold rolling processes

Cold-rolled steel is at the centre of the metal processing industry and is produced by the process of cold rolling. In contrast to hot rolling, this process takes place at temperatures far below the recrystallisation temperature of the metal, usually between room temperature and around 150 °C for steel. These low temperatures allow the microstructure of the material to be precisely fine-tuned, resulting in improved mechanical properties and a finer surface finish. While hot rolling makes the metal more pliable, cold rolling gives the steel increased strength and hardness, making it particularly suitable for applications that demand the highest levels of robustness and resilience.

Corrosion protection and surface finishing through hot-dip galvanising process

In this process, the steel substrate is immersed in liquid zinc, creating a permanent zinc coating on the surface. This layer not only provides excellent corrosion protection, but also helps to improve the structure of the steel. Hot-dip galvanising eliminates undesirable surface defects and improves the adhesion of coatings. In addition, the alloy formation between steel and zinc leads to increased strength and hardness of the material. Hot-dip galvanised steel is therefore widely used in construction, the automotive industry and other areas that require high resistance to corrosion and mechanical stress.

Improved surface quality thanks to electrolytic galvanising processes

Electrolytically galvanized steel is a versatile material that is produced through the process of electrolytic galvanizing. Electrogalvanized steel is used in a variety of applications, including automotive parts, household appliances and building components, where an attractive finish and long-term corrosion protection are required. In this process, the steel is immersed in an electrolyte solution and exposed to an electric current, depositing a thin, uniform layer of zinc on the surface of the steel. This coating provides effective corrosion protection that protects the underlying metal from moisture, chemicals and other environmental influences. In addition to corrosion resistance, electrolytic galvanizing improves the surface quality of the steel by creating a smooth, uniform coating that improves the appearance of the material and protects it from scratches and abrasion.

Natural protection and appealing surface

Oiled steel is defined by its versatile applications and the special treatment of its surface. Through the process of surface oiling, a thin layer of oil is applied to the steel, which not only protects against corrosion but also improves its appearance. This layer of oil forms a natural barrier against moisture and other environmental influences that could threaten the surface of the steel. At the same time, oiling gives the steel a characteristic smoothness and subtle lustre that enhances its aesthetics and protects it from the marks of daily use. Oiled steel is used in a variety of applications, from interior design to furniture manufacturing, where a perfect balance between protection and aesthetic appeal is required.

The robustness of the untreated

Unoiled steel is a raw material characterised by the lack of surface coatings. In contrast to oil-coated variants, unoiled steel retains its natural texture, which makes it particularly attractive for certain applications. Without an oil coating, the surface of the steel remains unchanged, making it accessible for specific machining and treatments. This condition opens up possibilities for welding, cutting and other shaping processes that require a clean metal surface. Unoiled steel is often used in applications where a natural, untreated aesthetic or specific surface finishes are desired, such as welded structures, mechanical components or architectural elements where the rawness of the material is important.

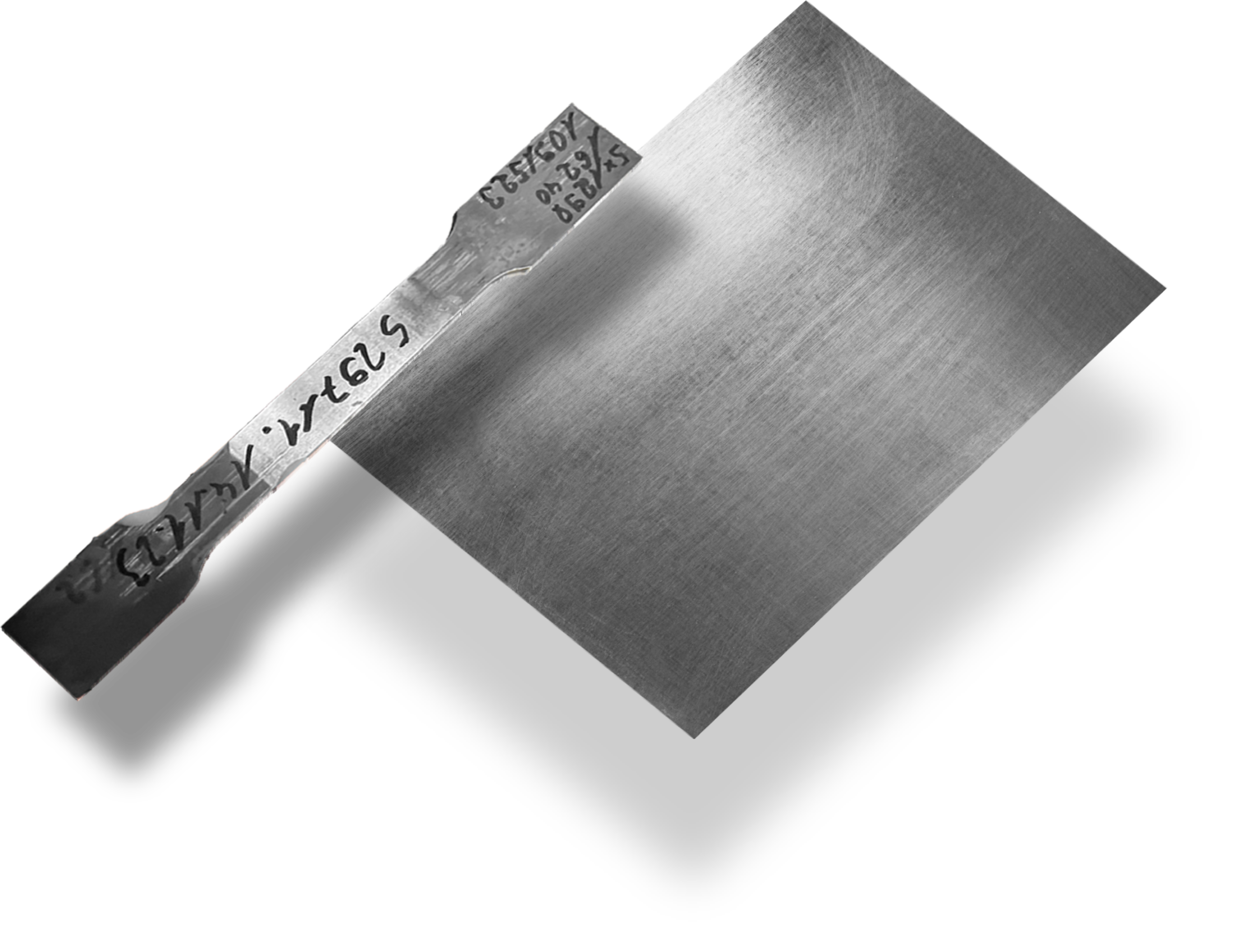

Corrosion protection and material preparation

In this process, surface impurities and oxide layers are removed in order to obtain a clean metal surface. Pickling not only cleans the surface, but also forms a microscopically thin protective layer that protects the metal from corrosion. This process improves the adhesion of coatings and improves the surface quality of the steel, making it suitable for further processing and applications. Pickled steel is used in a variety of industries, including the chemical, food and automotive industries, where a clean surface and effective corrosion protection are essential.